|

Sulfide Stress Cracking Corrosion (SSC)

Price 7999.0 INR/ Sample

Sulfide Stress Cracking Corrosion (SSC) Specification

- Mitigation Methods

- Material selection, environmental monitoring, stress reduction

- Type

- Sulfide Stress Cracking Corrosion (SSC)

- Risk Factors

- High hardness, tensile stress, H2S concentration

- Common Locations

- Downhole tubing, pipelines, pressure vessels

- Crack Initiation

- At stress concentrations or metallic flaws

- Affected Industries

- Oil & gas, petrochemical

- Failure Mode

- Brittle cracking of metals

- Test Method

- NACE TM0177

- Environmental Requirement

- Presence of wet H2S

- Applicable Material

- High-strength steels, especially in sour oil and gas environments

- Standard Reference

- NACE MR0175 / ISO 15156

- Operating Conditions

- High pressure and low to moderate temperature

- Corrosive Agent

- Hydrogen sulfide (H2S)

- Inspection Techniques

- Ultrasonic testing, magnetic particle inspection

Sulfide Stress Cracking Corrosion (SSC) Trade Information

- Minimum Order Quantity

- 1 Sample

- Payment Terms

- Cheque

- Main Domestic Market

- All India

About Sulfide Stress Cracking Corrosion (SSC)

| Corrosion Type | NACE |

| Testing Standards | NACE TM 0177 |

| Location/City | Pan India |

| Industry Body Standards | NACE |

| Testing Type | NACE Testing |

| Usage/Application | Energy And Chemical |

| Technique | NACE |

| Preferred Analysis Technique | Electro chemical Monitoring |

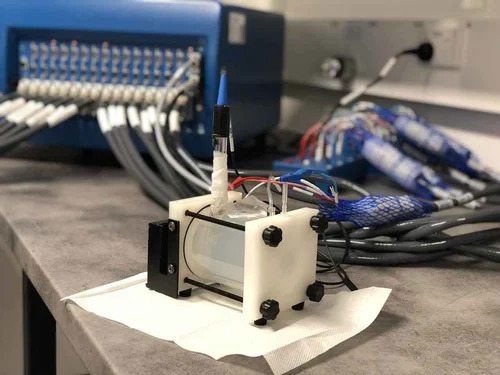

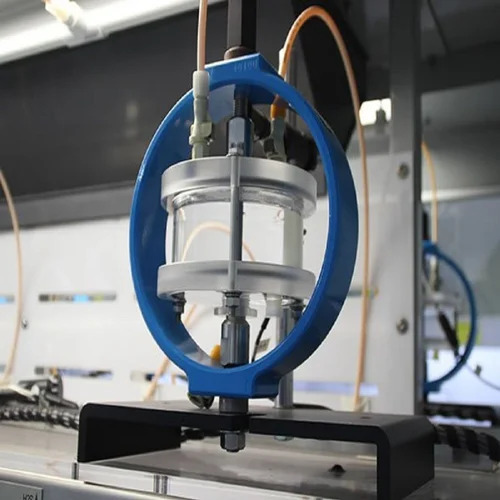

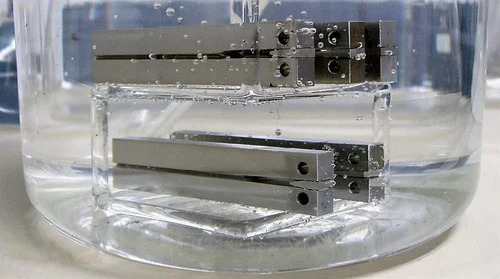

Mett-Bio Metallurgical Testing & Services with its state of the art equipment setup consisting of Two-point bend, Four point bend, C-Ring setups and experienced personnel conducts SSC testing as per Methods A, B, C and D test for resistance of carbon and low alloy steels and CRAs. These

Tests are performed in our ISO 17025:2005 NABL accredited lab under the standard sour conditions or as per specific field conditions.

NACE TM0177, Method A - Constant Load (Tensile) Test

NACE TM0177, Method B - Bent-Beam Test (Two Point , Four Point)

NACE TM0177, Method C - C-Ring Test

NACE TM0177, Method D - Double-Cantilever-Beam (DCB) Test

Mett-Bio Metallurgical Testing & Services has in housedeveloped AUTOCLAVE for simulating high Pressure and highTemperature (300C) conditions which prevails in refineries and chemical industries.

Failed test pieces are examined for crack sensitivity ratio, crack length ratio and crack thickness ratio using our optical microscopes.

Typical Outputs:

Time To Failure

Applied Stress Vs Log Of Time To Failure (Under Constant Load Conditions)

Apparent Threshold Stress (Under Circumferential Loading)

Threshold Stress Intensity Factor

Crack Velocity

Crack Growth Rate,

Stress Intensity Factor

Threshold Stress Intensity Factor.

Additional Information:

- Delivery Time: As per Test Schedule

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Corrosion Testing Service Category

|

METT-BIO METALLURGICAL TESTING & SERVICES

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry